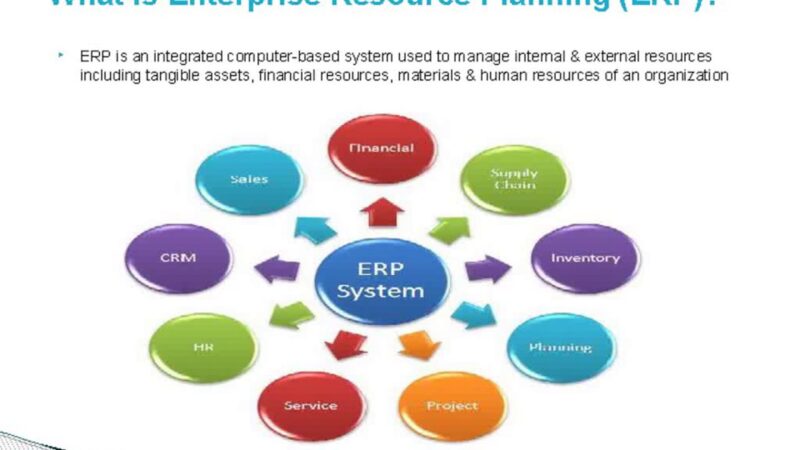

Manufacturing industries encounter distinct challenges in operations, inventory, and supply chain management. ERP software for manufacturers plays a vital role in addressing these issues. Discover the significance of ERP software for manufacturing businesses and how it enhances efficiency.

TOC

Understanding ERP Software for Manufacturers

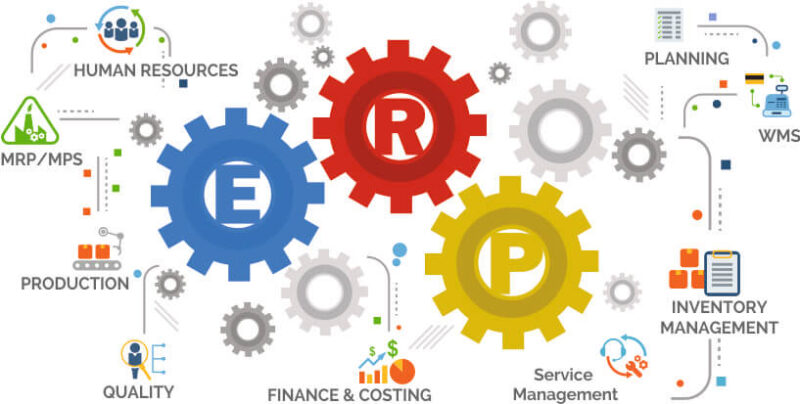

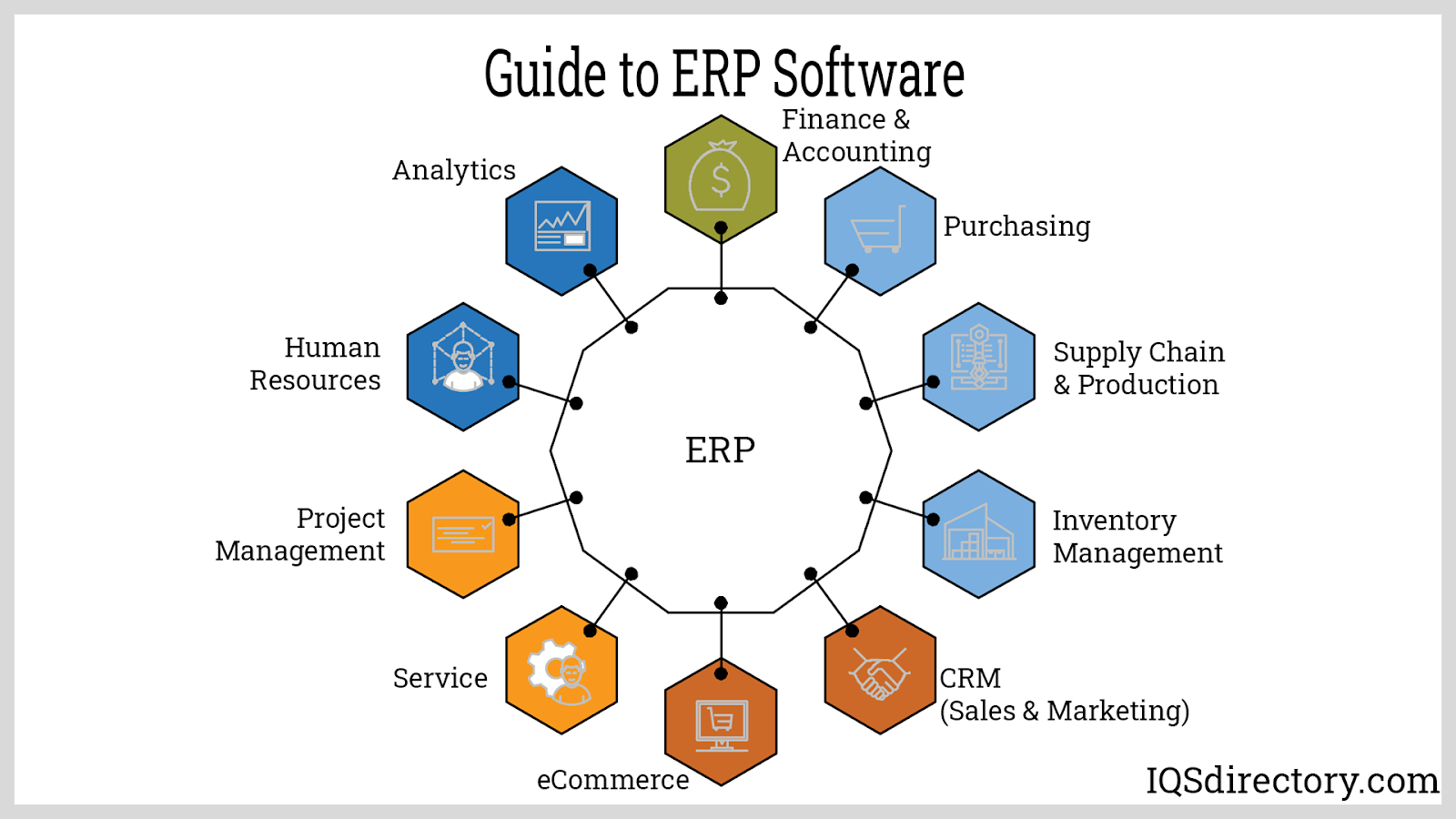

ERP software for manufacturers is a powerful tool that integrates and streamlines various aspects of manufacturing operations. This comprehensive solution centralizes production planning, inventory management, financial tracking, and customer relationship management in one platform.

By automating processes and enhancing efficiency, ERP software empowers manufacturers to reduce costs and boost productivity. It eliminates manual data entry, providing real-time access to crucial information for informed decision-making and business growth.

Why Implement ERP Software in Manufacturing?

In today’s competitive manufacturing landscape, agility and responsiveness are key. ERP software offers numerous advantages that can give manufacturers a competitive edge.

Efficient inventory management is vital for meeting customer demands while controlling costs. ERP software offers robust inventory management features to track stock levels, monitor usage, and automate reordering processes. Accurate inventory data helps prevent stockouts and ensures timely deliveries, enhancing customer satisfaction.

Production planning and scheduling can be complex without the right tools. ERP software enables manufacturers to optimize production processes by creating realistic plans, scheduling tasks, and allocating resources efficiently. This optimization minimizes downtime, maximizes productivity, and improves order fulfillment speed, leading to enhanced customer satisfaction.

In conclusion, ERP software revolutionizes manufacturing operations, inventory management, and supply chain processes. Tailoring ERP software to specific needs can unlock a manufacturer’s full potential, streamline operations, and drive sustainable growth. Explore the key features and benefits of ERP software for manufacturers in the upcoming section.

Key Features of ERP Software for Manufacturers

To understand the significant advantages of ERP software for manufacturers, it’s crucial to explore its key functionalities. Let’s delve into the essential features that make ERP software a game-changer in the manufacturing industry:

- Inventory Management

Effective inventory management is critical for meeting customer demands and controlling costs. ERP software provides robust inventory management capabilities, enabling businesses to track stock levels, monitor usage, and automate reordering processes. Real-time visibility into inventory data helps prevent stockouts, reduce excess inventory, and ensure timely order fulfillment.

- Production Planning and Scheduling

Efficient production planning and scheduling are essential for optimizing operations. ERP software allows businesses to create realistic production plans, set accurate schedules, and allocate resources efficiently. Automation of these processes helps minimize downtime, boost productivity, and maintain a smooth production flow.

- Supply Chain Management

A well-organized supply chain is vital for manufacturing success. ERP software offers comprehensive supply chain management functionalities, empowering manufacturers to oversee every aspect of their supply chain. From raw material sourcing to shipment tracking and supplier management, ERP software enhances visibility, reduces lead times, and enhances overall supply chain performance.

Quality Control and Assurance: Ensuring top-notch quality is essential for manufacturers to meet customer expectations. ERP software features robust quality control and assurance modules for monitoring and managing quality throughout the manufacturing process. From inspections and testing to compliance tracking and corrective actions, ERP software guarantees consistent product quality and regulatory adherence.

Financial Management and Reporting: Effective financial management is critical for the enduring success of manufacturing businesses. ERP software offers comprehensive financial management capabilities, empowering manufacturers to track expenses, handle budgets, and generate precise financial reports. With real-time financial data available, businesses can make informed decisions, pinpoint cost-saving opportunities, and ensure financial stability.

CRM (Customer Relationship Management): Establishing strong customer relationships is crucial for manufacturers to excel in a competitive market. ERP software provides integrated CRM functionality for managing customer interactions, tracking sales, and delivering exceptional customer service. With a centralized customer database and automated communication tools, manufacturers can enhance customer satisfaction and drive repeat business.

Integration with Other Systems: ERP software seamlessly integrates with essential systems like HR, payroll, and e-commerce platforms. This integration eradicates data silos, enhances data accuracy, and promotes efficient cross-functional collaboration. By linking various systems, ERP software builds a unified ecosystem that streamlines operations, boosts productivity, and enhances overall business performance.

Discover the remarkable benefits of ERP software for manufacturers in the upcoming section.

ERP Software Benefits for Manufacturers: Boost Efficiency and Cut Costs

In the competitive landscape of manufacturing, ERP software plays a vital role in enhancing operations. Discover the advantages offered by ERP software:

Enhanced Productivity: ERP software streamlines processes, minimizes errors, and boosts efficiency through automation. Real-time insights empower employees to work effectively with automated workflows and optimized resource management, resulting in improved productivity and quicker project completion.

Cost Savings and Operational Efficiency: Streamlined operations simplify complex supply chains and interdepartmental coordination. By reducing bottlenecks and errors, ERP software minimizes downtime and operational costs. Automating tasks enhances resource allocation, leading to significant cost savings for manufacturers.

Inventory Management: ERP software provides real-time inventory visibility, enabling manufacturers to track stock levels, monitor usage, and automate replenishment. With precise inventory data, manufacturers prevent stockouts, ensuring timely deliveries and enhancing customer satisfaction while reducing carrying costs and waste.

Real-time Data and Reporting for Smart Decision-Making

ERP software streamlines data collection and analysis across departments, empowering manufacturers with instant insights into their operational performance. By leveraging precise, current information, decision-makers can drive data-informed strategies and swiftly adapt to market dynamics. Additionally, ERP systems provide robust reporting tools, allowing manufacturers to create tailored reports, spot trends, and pinpoint areas for enhancement. This data-centric approach fosters proactive decision-making and equips manufacturers to outshine competitors.

Enhanced Collaboration and Communication Across Teams

Effective teamwork and communication are core to success in manufacturing. ERP solutions dismantle data barriers and encourage cross-departmental collaboration through a unified information hub. By facilitating seamless data exchange and communication among key departments like production, inventory, finance, and sales, ERP software promotes teamwork, minimizes misunderstandings, and boosts overall productivity.

Adaptability and Scalability for Business Growth

Manufacturing enterprises are ever-evolving. ERP software provides the flexibility and scalability needed to adapt to changing business landscapes. Whether expanding into new markets, introducing product lines, or acquiring subsidiaries, ERP systems can grow alongside your business. This scalability ensures that your software investment remains relevant and supports your business expansion.

In the following section, we will explore essential factors for manufacturers to consider when selecting ERP software tailored to their specific requirements. Stay tuned for valuable insights!

Key Factors to Consider When Choosing ERP Software for Manufacturers

Selecting the best ERP software for your manufacturing business requires careful evaluation of specific factors that align with your needs. Here are essential considerations to guide your decision:

-

Tailored Industry Functionality

Each manufacturing sector has distinct requirements. Opt for ERP software with industry-specific features to address challenges unique to automotive, electronics, or food production. Tailored functionality ensures smoother implementation and improved outcomes.

-

Customization Flexibility

Every manufacturing operation is unique. Choose ERP software that can be customized to match your workflows. Look for flexibility in configuration to align the system with your business needs, promoting seamless integration and efficiency.

-

User-Friendly Interface and Implementation

Transitioning to new software can be challenging. Prioritize ERP solutions with intuitive interfaces for easy navigation, reducing training time for employees. Seek software that offers comprehensive implementation support and training for successful adoption.

-

Integration with Existing Systems

Seamless integration with current systems is vital. Assess ERP software compatibility with your infrastructure, including accounting software, CRM systems, and production machinery. Smooth integration prevents data silos and promotes real-time information sharing, enhancing operational efficiency.

Vendor Support and Training for ERP Software

Selecting an ERP software provider that offers dependable support and training is crucial for a smooth implementation. Prioritize vendors known for consistent support, frequent updates, and responsive customer service. This ensures you have the needed assistance whenever issues arise or additional training is required.

Cost and Return on Investment (ROI) Considerations

Assess the implementation costs and potential ROI of ERP software for your business. Evaluate pricing structures, such as licensing fees, maintenance costs, and optional modules. Determine potential ROI by weighing efficiency gains, cost reductions, and enhanced productivity.

By thoughtfully evaluating these aspects, you can opt for an ERP software solution that meets your manufacturing business’s requirements and positions you for long-term success. Stay tuned for real-life case studies illustrating successful ERP software implementations in manufacturing.

Case Studies: Successful ERP Software Implementation for Manufacturers

When considering the implementation of ERP software for manufacturers, real-life success stories offer valuable insights into the benefits and impact it can have on businesses. Let’s delve into a few case studies that showcase the positive outcomes achieved through the adoption of ERP software.

Here are three real-world instances showcasing successful ERP software implementations in the manufacturing sector across the United States, Japan, and China:

-

Ashley Furniture (USA):

- Sector: Furniture Manufacturing

- ERP Solution: Oracle Cloud ERP

- Challenges: Ashley Furniture, a prominent American furniture manufacturer, encountered issues related to fragmented data among departments, ineffective production planning, and sluggish inventory management. These challenges led to inefficiencies in their operations, impacting their overall performance in the market.

- Achievements: Through the adoption of Oracle Cloud ERP, Ashley Furniture experienced a significant transformation. The implementation resulted in enhanced collaboration among design, production, and sales teams. Additionally, it led to streamlined production scheduling and improved resource utilization. The immediate inventory visibility provided by the ERP system helped in reducing stockouts, thus enhancing customer satisfaction and optimizing operational efficiency. The cost reduction achieved through this initiative further solidified Ashley Furniture’s position in the industry.

-

NSK Ltd. (Japan):

- Sector: Bearing Manufacturing

- ERP Solution: SAP S/4HANA

- Challenges: NSK, a renowned Japanese bearing manufacturer, required a modernized ERP system to enhance global operations and meet changing customer needs. The existing systems were no longer sufficient to support the company’s growth and evolving market demands, prompting the need for a comprehensive solution.

- Achievements: Deployment of SAP S/4HANA brought about a paradigm shift in NSK’s operations. The implementation standardized processes across global sites, ensuring consistency and efficiency in their operations worldwide. The enhanced data accuracy and real-time analytics provided by the new ERP system empowered NSK to make data-driven decisions swiftly, improving their overall performance. Furthermore, the strengthened collaboration with suppliers and distributors enabled NSK to build stronger partnerships and adapt more effectively to market dynamics.

-

Haier (China):

- Sector: Home Appliance Manufacturing

- ERP Solution: Custom ERP system integrating Oracle and SAP components

- Challenges: Haier, a significant Chinese home appliance manufacturer, aimed to lead in smart manufacturing and personalize products for individual consumers. The company recognized the need to embrace digital transformation to stay competitive and cater to the evolving preferences of consumers in the digital age.

- Achievements: Haier’s innovative approach of developing a custom ERP system integrating Oracle and SAP components proved to be a game-changer. The system enabled Haier to incorporate smart factory technologies such as IoT and AI, enhancing their manufacturing processes and product offerings. The mass customization capabilities facilitated by the ERP system allowed Haier to tailor products according to individual customer preferences, boosting customer satisfaction. The improved production visibility and reduced lead times resulting from the implementation enhanced Haier’s operational efficiency and brand loyalty, positioning them as a leader in the industry.

These examples illustrate the manifold benefits ERP systems offer to manufacturers, ranging from enhanced efficiency and cost savings to greater flexibility and customer satisfaction. It’s crucial to recognize that the choice of ERP software and its implementation specifics will vary based on the company’s size, industry, and specific requirements.

In summary, these case studies demonstrate the tangible advantages of ERP software for manufacturers. From improved efficiency and shorter lead times to enhanced quality control and optimized supply chain management, ERP software emerges as a powerful tool for manufacturing enterprises, enhancing their competitiveness and fostering sustainable growth. Stay tuned for insights on the key considerations when selecting the right ERP software for your manufacturing needs.

Conclusion

In today’s dynamic manufacturing landscape, strategic adoption of appropriate ERP software is essential for maintaining competitiveness and thriving in the industry. Tailored ERP solutions for manufacturers offer numerous benefits, streamlining processes, boosting productivity, and fueling business expansion.

By leveraging the functionalities of ERP software, manufacturers can efficiently manage their inventory, production scheduling, supply chain, and financial workflows. The centralized nature of ERP platforms enables real-time data access and reporting, empowering enterprises to make informed decisions and optimize business operations.

The advantages of ERP software for manufacturers are abundant. It boosts operational efficiency and productivity by automating manual tasks and streamlining procedures. Enhanced inventory management allows manufacturers to reduce stock shortages and ensure timely customer deliveries, enhancing satisfaction and loyalty.

The real-time data and reporting provided by ERP software offer manufacturers a comprehensive view of their operations, facilitating data-driven decision-making. Improved interdepartmental collaboration and communication further enhance operational efficiency and reduce errors.

Scalability and adaptability are crucial for manufacturers navigating changing market landscapes. ERP software provides seamless scalability, supporting business expansion without interruptions.

When choosing an ERP software solution for your manufacturing enterprise, consider industry-specific features, customization options, ease of use, integration capabilities, support services, and cost-effectiveness. These factors will ensure that the ERP software meets your unique manufacturing needs and achieves desired outcomes.

At petfoodsreviews.com, we understand the challenges faced by manufacturers and offer a tailored ERP software solution designed specifically for the industry. With our expertise and commitment to delivering high-quality software, we are prepared to streamline your operations, enhance productivity, and elevate your manufacturing enterprise to new heights.